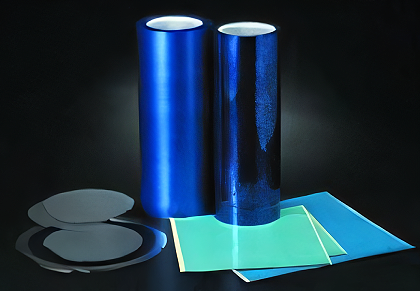

UV Dicing Tape

UV dicing tape is a type of tape used in the semiconductor industry to hold semiconductor chips in place during the dicing process. Dicing is the process of cutting a wafer of semiconductor material into individual chips. UV dicing tape is made of a thin, flexible material with a UV-curable adhesive. The tape is applied to the wafer and then exposed to UV light. The UV light cures the adhesive, which bonds the tape to the wafer. The tape helps to keep the chips in place during the dicing process and prevents them from breaking.

Base Material : PO Film, PET Film

Adhesion(gf/25mm) : 600~1200 (Before UV), 20~30 (After UV)

Grade : DU-390 Series, DU-9177 Series, DU-130P

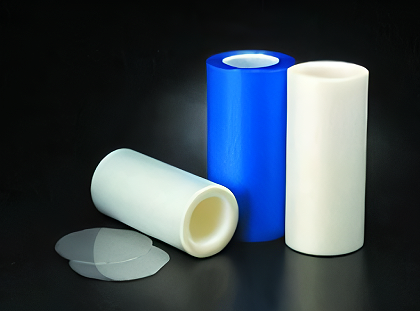

Non UV Dicing Tape

Non-UV dicing tape is a type of tape used in the semiconductor industry to hold semiconductor chips in place during the dicing process. Dicing is the process of cutting a wafer of semiconductor material into individual chips. Non-UV dicing tape is made of a thin, flexible material with a pressure-sensitive adhesive. The tape is applied to the wafer and then pressed down firmly. The adhesive holds the chips in place during the dicing process and prevents them from breaking.

Material : PVC

Adhesion(gf/25mm) : 60~120

Grade : DN-280 Series